Description

-

Custom syntetized oligomer by BlueCast, not available to market, patent is going to be applied.

-

Curing triggering tuned to maximize antialias smoothing

-

No monomer inside, no smell

-

No aggression on plastic parts (tested on PS, PMMA)

-

No postcuring needed for casting

-

No shrinkage

-

No primer needed

-

Less spreeing needed, oxygen for burnout is released by resin during burnout (less scrap metal, less work on metal)

-

Easy welding with wax, forget about pattern lost into investment

-

Can be polished, engraved, drilled (postcure is needed) AAAAA

-

Low viscosity, easier to recover uncured resin from models, easy to wash

-

No preheating required

-

Very little hygroscopic while liquid, no water absorption while printed

-

Atoxic, solvent free, very low phospine content, very low skin irritant

-

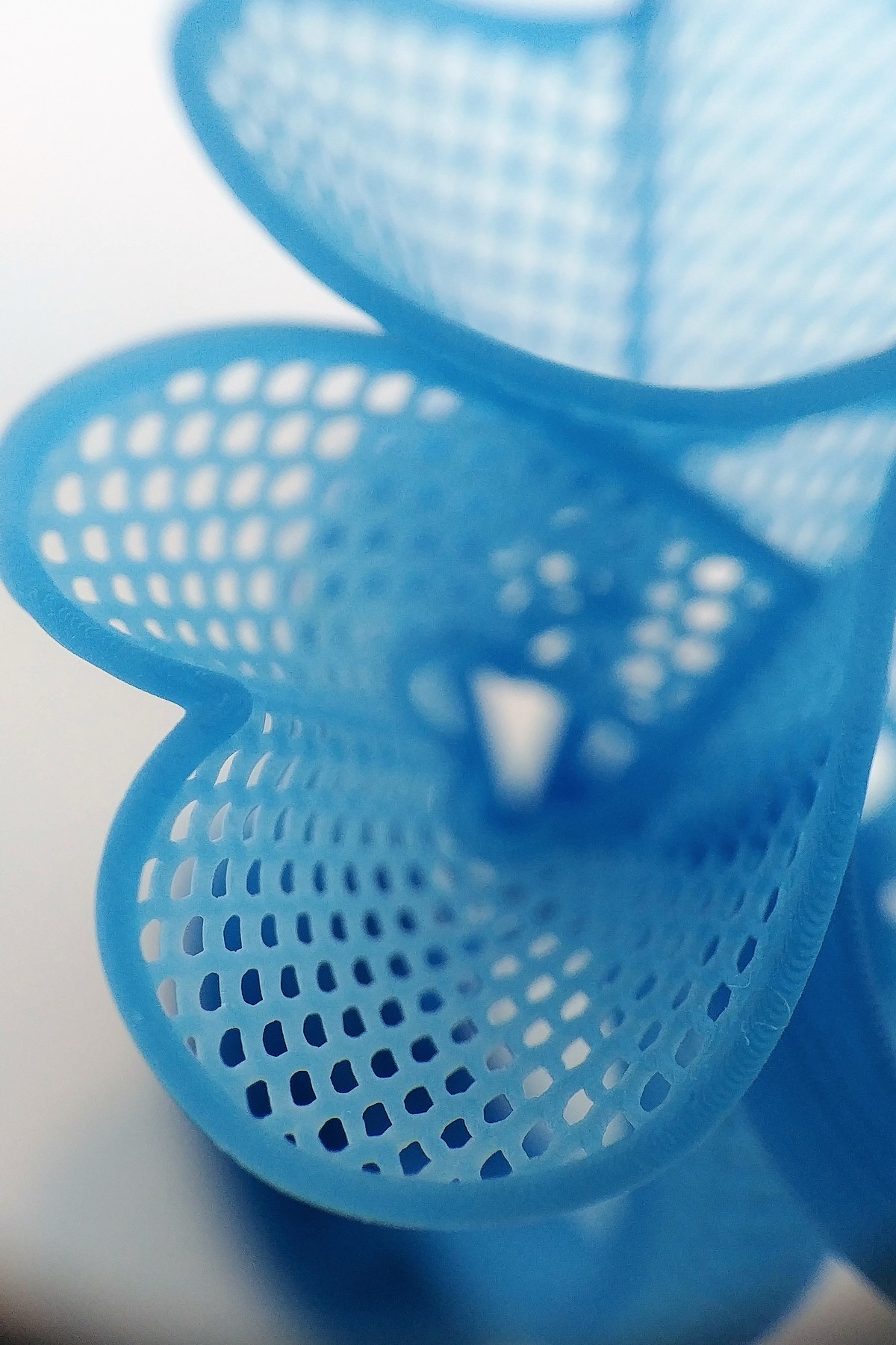

Fast and detailed – Hard but elastic, good compression set

-

Cleaner burnout, 0,00% ash residual

-

Solvent free

-

Suitable for fast burnout

-

Full burnout also at lower temperature (750 C°)

-

No expansion during burnout, sublimation starts at 130 Celsius

-

Burnout will not release aggressive chemicals to investment (80% of burnout is composed by carbon dioxide and water and oxygen that is used to complete combustion)

-

Low tension surface (better surface, no need to treat models with spray or dip baths) – Excellent dimensional stability in time, no need to stock in cold/dark places

-

Available for low power LCD, DLP and laser printers

-

Shelf life 2 years

.

Fully compatible with all LCD printers and with all DLP machines with 385/405 nm Projector and FEP tank.

X5 Formlabs Blue Cast castable resin, compatible for SLA 3D printers available upon request.

3D printing Castable resin X5 characteristics

| Package | 0.5 kg | |

| Color | light blue | |

| Post UV cure | not needed | |

| Recommended castaed products | fine detail jewellery, pavè |

BlueCastX5 Details MSDS Burnout

Reviews

There are no reviews yet.