Description

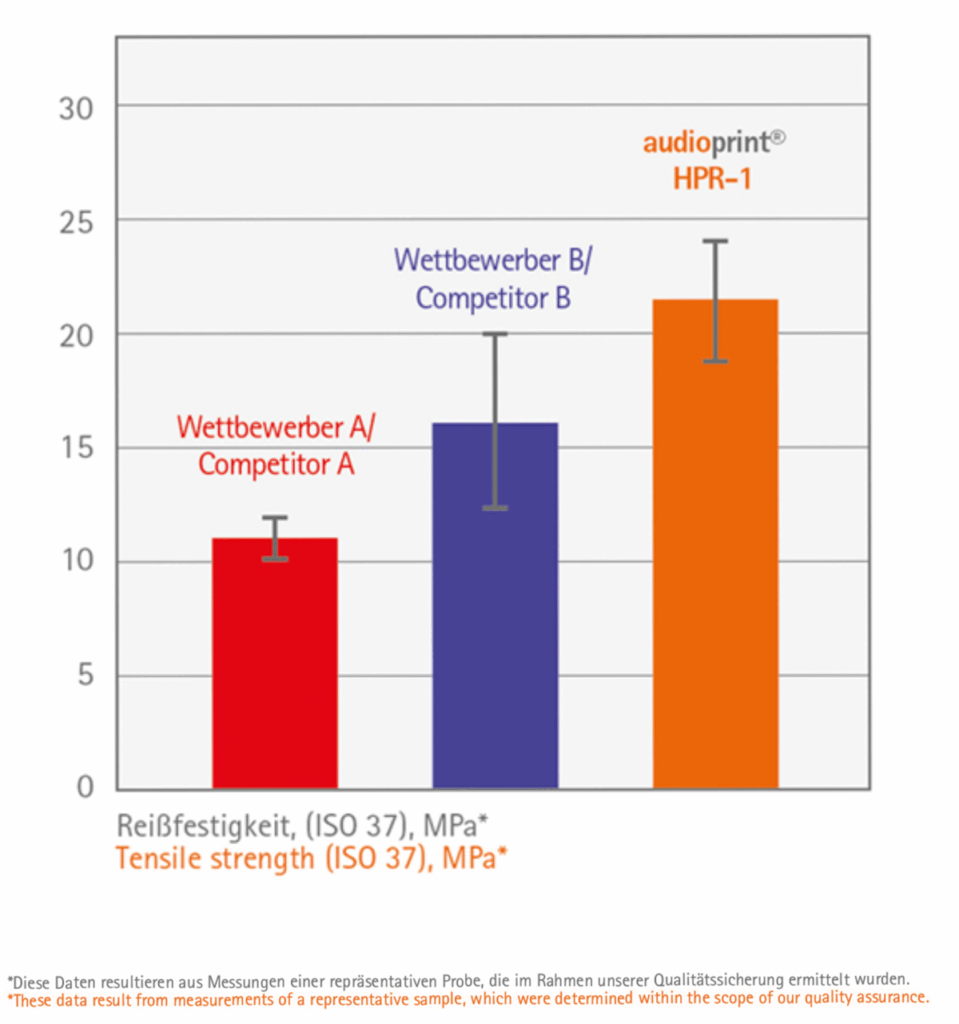

Pro3dure´s 3D printing resins of the audioprint HPR series are the ideal choice for additive manufacturing of hearing protection earmolds for use in work areas with the highest requirements. Hearing protection made of audioprint HPR-1 features outstanding chemical-physical properties such as the highest tensile strength in its class. In addition, audioprint HPR-1 earpieces have a reversible thermo effect. The material is ”hard“ when inserted into the ear canal and then becomes flexible due to body temperature, thus providing a comfortable and natural wearing comfort. This effect increases the acceptance of wearing hearing protection and thus occupational safety. Hearing protection made of audioprint HPR-1 can be optimally sealed with audioprint lacquer L-2 FLX. audioprint HPR-1 is available in clear-transparent, white-opaque, blue-transparent, red-transparent and 3 neon signal colors.

Advantages:

- outstanding properties

- highest tensile strength in its class

- reversible thermo effect

- natural wearing comfort

- increase of work safety

Manufacturing process:

- Prepare data (CAD & build preparation).

- Choose process parameters (build style, etc.).

- Transfer prepared data to 3D printing device.

- Prepare 3D printing – shake bottle.

- Fill resin tank of 3D printing device.

- Build the parts.

- Clean parts (with IPA ≥ 97 % or equivalent cleaning agent), approx. 4 min. in an ultrasonic bath or equivalent device – precleaning recommended.

- Dry parts, until there are no residues of IPA or equivalent cleaning agent.

- Post curing (4 min.): inert atmosphere recommended (use adequate light curing device).

- Finish parts.

Important

-

To avoid detrimental effects on material quality do not expose the liquid material to irradiation under any circumstances.

-

Deviations from the described manufacturing process may lead to different mechanical and optical properties of the audioprint HPR-1 temporary material.

-

Ensure personal protective gear during processing.

-

Caution: Polymerized resins are chemically resistant – avoid stains on clothing!

-

Avoid any contact with skin and eyes. In case of accidental contact, rinse with adequate running water, consulting a doctor if necessary.

-

The lot number and the best before date are indicated on each audioprint HPR-1 temporary packaging. In case of claims please always indicate the lot number of the product.

-

Do not use the product after expiry of the best before date.

Safety notice

The company I.D.M di Marin Davide is not a manufacturer of medical materials or devices. The material sold on this site is neither produced nor controlled by the company I.D.M. di Marin Davide, who in no case can be held responsible for any damage caused by use or application of the material, which must only be used on suitable machines and by specialized personnel, exclusively for the purpose indicated, according to the manufacturer’s instructions. For resins with European certification, the properties of the finished product vary according to the entire printing and post-curing process; refer to the manufacturer for any information about it.

Reviews

There are no reviews yet.