Description

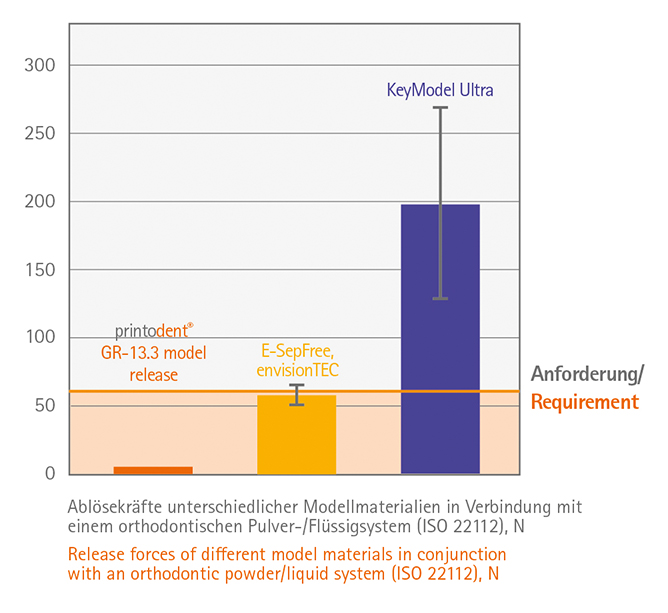

Pro3dure´s printodent GR-13.3 model release was specially developed for orthodontic applications and eliminates the need for additional release agents when using 2-component powder/liquid resins with 3D-printed dental models. Through pro3dure´s new ”release“ technology, it is possible for the first time to provide a material that has an integrated separation effect. This is not due to the addition of fillers such as waxes, which can segregate from the resin matrix and lead to unstable builds or defective components. Furthermore, due to its low viscosity, components made of printodent® GR-13.3 model release are easy to clean, thus enabling an efficient finishing process. It is suitable for many othodontic powder/liquid systems.

Advantages:

- no isolating agents necessary

- pro3dure´s ”release“ technology

- integrated separating effect

- low viscosity

- efficient post-processing

Available in white (opaque) color for 3D printers that emit light at ≤ 405 nm.

COMPATIBLE WITH DLP/LCD/SLA 3D PRINTERS.

Specifications for printodent GR-13.3 model release

| Property | Requirement | Result *** | Standard |

|---|---|---|---|

| Ultimate flexural strength | ≥ 10 MPa | 15 MPa | ISO 20795-1 ** |

| Flexural modulus | ≥ 250 MPa **** | 400 MPa | ISO 20795-1 ** |

| Flexural strain (at break) | ≥ 8 % **** | 20 % | ISO 20795-1 ** |

| Bond strength to 2-component powder/liquid resins | < 15 N **** | 2 N | ISO 22112 ** |

| Shore hardness | n.a./n.a. * | 65 D | DIN 48-4 |

| Viscosity (23°C) | n.a./n.a. * | 50 mPas | DIN 53019-1 |

* not applicable

** on the basis

*** these data result from measurements of a representative sample, which were determined within the scope of our quality assurance

**** according to internal design and requirement specifications

How to use

Preparation:

-

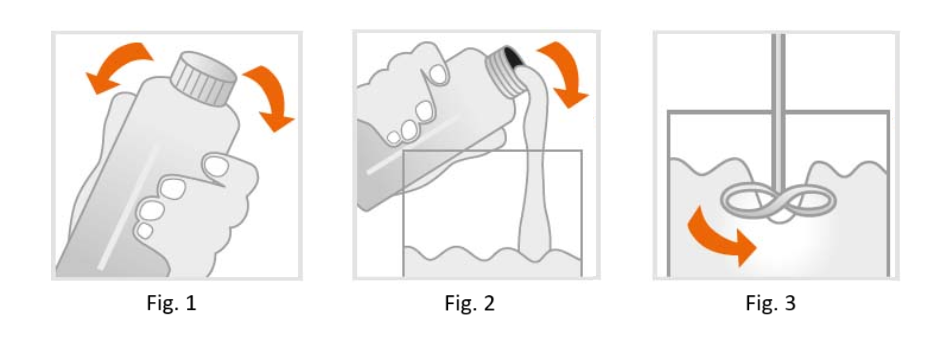

GR-13.3 model release bottles should be well shaken before use (Fig.1).

-

Make sure that GR-13.3 model release temperature is within 23 °C to 30 °C. If possible, always store a bottle GR-13.3 model release in your production unit in order to avoid temperature differences during refilling.

-

Impurities due to operational mistakes cannot be excluded. With respect to the low viscosity of the resin it is possible to filtrate GR-13.3 model release and stir it on a regular base (Fig.3). To avoid bubbles let GR-13.3 model release rest for 1 hour before usage.

Manufacturing process:

- Prepare data (CAD & build preparation).

- Choose process parameters (build style, etc.).

- Transfer prepared data to 3D printing device.

- Prepare 3D printing – shake bottle.

- Fill resin tank of 3D printing device (Fig.2). Bubbles can be removed with a clean spatula or by a recoater routine.

- Build the parts.

- Clean parts (with IPA ≥ 97 % or equivalent cleaning agent)

approx. 10 min. in an ultrasonic bath or equivalent

device – precleaning recommended. - Dry parts, until there are no residues of IPA or equivalent

cleaning agent. - Post curing (2 x 5 min. / wall thickness > 2.5 mm: 2 x 10 min.):

inert atmosphere recommended (use adequate light

curing device). - Finish parts. The dental objects created with GR-13.3 model release can be coated and repaired as usual.

Important

-

To avoid detrimental effects on material quality do not expose the liquid material to irradiation under any circumstances.

-

Deviations from the described manufacturing process may lead to different mechanical and optical properties of the GR-13.3 model release material.

-

Ensure personal protective gear during processing.

-

Caution: Polymerized resins are chemically resistant – avoid stains on clothing!

-

Avoid any contact with skin and eyes. In case of accidental contact, rinse with adequate running water, consulting a doctor if necessary.

-

The lot number and the best before date are indicated on each GR-13.3 model release packaging. In case of claims please always indicate the lot number of the product.

-

Do not use the product after expiry of the best before date.

Safety notice

The company I.D.M di Marin Davide is not a manufacturer of medical materials or devices. The material sold on this site is neither produced nor controlled by the company I.D.M. di Marin Davide, who in no case can be held responsible for any damage caused by use or application of the material, which must only be used on suitable machines and by specialized personnel, exclusively for the purpose indicated, according to the manufacturer’s instructions. For resins with European certification, the properties of the finished product vary according to the entire printing and post-curing process; refer to the manufacturer for any information about it.

Reviews

There are no reviews yet.