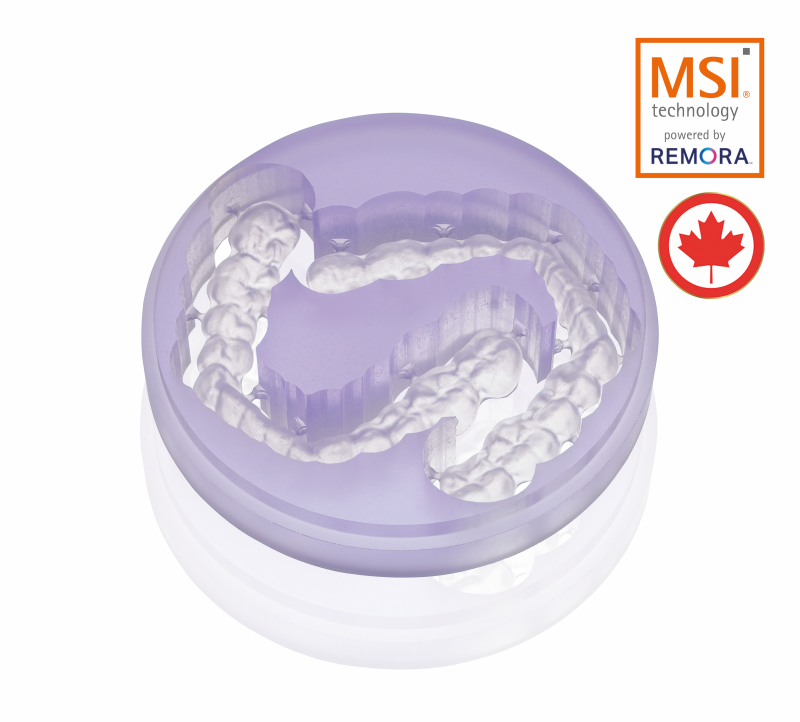

Description

The thousands of times proven THERMEO round is now also available as an MSI (Multi Species Inhibition) version. This makes it the world‘s first biomimetic milling disc in its class, which naturally prevents the adhesion of biofilms in the oral environment using pro3dure´s unique MSI® technology. It copies a natural process, such as that used by the red alga Delisea. A natural substance (lactam) anchored in the dental material interferes with the communication of bacteria, the so-called “quorum sensing”. This significantly reduces the formation of biofilms or their adhesion. This effect is not due to antibacterial additives, which may lead to bacterial resistance. In the course of this, improved oral hygiene is achieved and thus less irritation of the soft tissue in accordance with the motto “Inspired by nature, addicted to function”.

Advantages:

- exceptional wearing comfort

- unique flexibility by thermomemory effect

- self adjusting

- no yellowing

- extreme durability

- long-lasting

- highest biocompatibility

- MSI® technology for the reduction of biofilms

Processing

- THERMEO | MSI milling blanks should be used only for the purpose of CAD/CAM production of dental occlusal splints. They can be used in all common CAD/CAM systems.

- Suitable cross-cut carbide cutters are to be used exclusively for the processing of the THERMEO | MSI material.

- THERMEO | MSI occlusal splints are designed and milled by CAD/CAM technology and qualified staff. After finishing, the thickness in the occlusal region of the splint must not be less than

0,9 mm. For aesthetic reasons, a labial reduction to 0,8 mm is permissible. Any corners and edges should be rounded off. - THERMEO | MSI splints can be removed from the milling blank by using suitable cross-cut carbide cutters or cutting discs suitable for composites. Carefully cut through the retaining strips without pressure.

- In order to avoid plaque accumulation subsequent polishing of the splints is essential. Please pre-polish with suitable silicone polishers and goat’s hair brushes. The high-luster polishing should be done with a corresponding polishing compound. As far as possible, please avoid heat generation during the polishing and

finishing of the THERMEO | MSI splint. This guarantees the optimal fitting of the splint. - Please note: Upon completion, use an ultrasonic bath with water at a maximum temperature of approx. 35 °C for cleaning. Cleaning solutions are not recommended.

- THERMEO | MSI powder liquid system must be used for repairs or addition of material in order to preserve the thermoplastic properties of the splint. The processing recommendations of the manufacturer must be taken in consideration.

Safety notice

The company I.D.M di Marin Davide is not a manufacturer of medical materials or devices. The material sold on this site is neither produced nor controlled by the company I.D.M. di Marin Davide, who in no case can be held responsible for any damage caused by use or application of the material, which must only be used on suitable machines and by specialized personnel, exclusively for the purpose indicated, according to the manufacturer’s instructions. For resins with European certification, the properties of the finished product vary according to the entire printing and post-curing process; refer to the manufacturer for any information about it.

Reviews

There are no reviews yet.