Description

THE FIRST CASTABLE WAX FOR LCD AND DLP PRINTERS

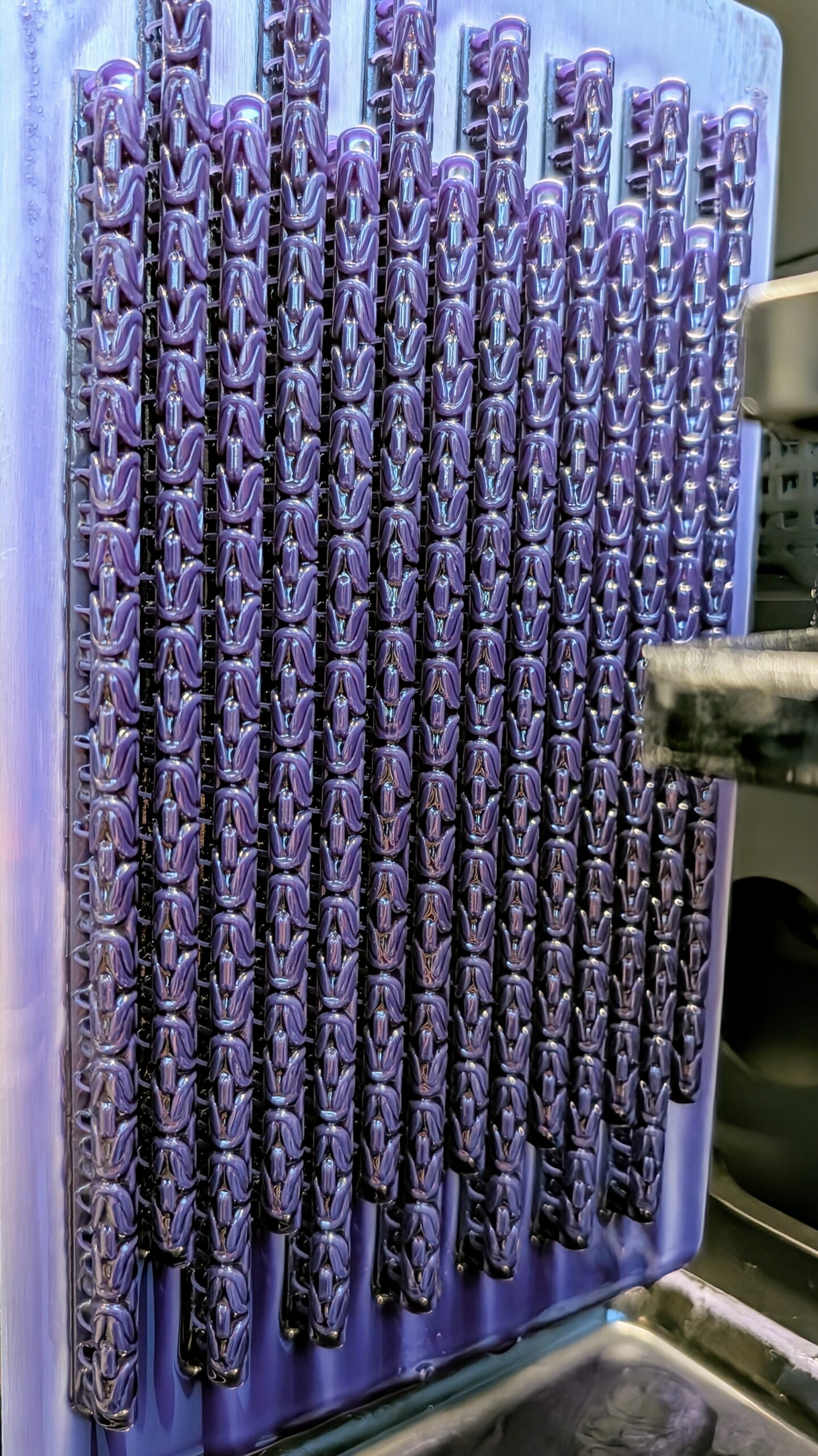

Step into the future of 3D printing for jewelry with X-Wax, the groundbreaking resin that redefines quality and reliability standards. Developed through years of research and innovation, X-Wax represents a paradigm shift in the micro-casting industry: a resin that is not just like wax but is wax, designed to simplify and enhance every step of the production process.

X-Wax is optimized for both 405nm and 385nm UV light, ensuring peak performance with any 3D printer. The 385nm UV wavelength provides shallower penetration, allowing for precise control over resin curing depth.

*Key Features*

- Liquid wax for 3D printing*: Thanks to its high wax content, X-Wax stands apart from any other resin on the market.

- Outstanding castability*: With over 80% real micro-casting wax content, it performs on par with traditional wax models.

- Universal compatibility*: Suitable for all casting investments and burnout cycles.

- Flawless burnout*: No ash or residue left behind.

- Absolute precision*: Guaranteed dimensional stability with no shrinkage or expansion.

- Easy to print*: Compatible with any LCD or DLP printer.

- Minimal bleeding*: Clean, sharp results with no resin build-up.

- Enhanced user experience*: Minimal odor and fumes during both printing and burnout.

- Simplified post-processing*: A quick alcohol wash is all you need for professional results.

- Health-conscious*: Made with materials that are not classified as hazardous.

- Environmentally friendly*: Over 80% of its composition comes from natural wax, reducing its environmental impact throughout production, use, and disposal.

- As it is made primarily of wax, X-Wax can solidify during storage

BlueCast X-Wax LCD/DLP details

| Size | 500G |

| Notes | Before opening the bottle, it is necessary to warm the product for 5 minutes at a temperature between 30 and 40 degrees Celsius. PAY ATTENTION, heating the resin above 60 degrees Celsius can irreversibly damage it. The manufacturer is not responsible for an incorrect use of the product. |

| Post UV cure | POST-PRINTING CLEANUP AND TREE PREPARATION 1. Wash the patters in IPA alcohol or Ethyl alcohol for 5 minutes. 2. Blow the prints with compressed air to remove excess uncured resin. 3. Perform a second wash in IPA clean alcohol for 3 minutes, then dry the prints again with compressed air. 4. For a more thorough cleaning, you can use 3D wash stations or ultrasonic cleaners. 5. Allow the models to rest for at least 15-20 minutes before assembling the casting tree. The washing is also effective with ethyl alcohol. |

| Recommended use | Traditional and standard designs; Solid parts and men’s rings |

Reviews

There are no reviews yet.