Description

Pro3dure´s 2 component THERMEO powder/liquid system is polymerized by heat and pressure (> 2 bar). Splints made out of THERMEO material are extremely break resistant. The thermoplastic flexibility provides greater, comfortable and tension-free wearing comfort.

For THERMEO Powder instructions for use see below.

THERMEO Liquid properties

THERMEO is flexible.

Who doesn‘t know it – “crooked impressions” during conventional impression taking or imperfections during intraoral scanning that lead to “data holes” on the surface of the generated data set? A conventional hard splint then wobbles on the plaster model and thus in the patient‘s mouth. The splint is subjected to greater stress at this point, the risk of fracture is significantly increased and the patient complains about a lack of wearing comfort. The unique THERMEO splint material compensates for such inaccuracies with its patented thermomemory effect. The THERMEO material becomes flexible at body temperature and adapts optimally to the tooth surface. This increases the wearing comfort of the splint and minimizes the risk of breakage. THERMEO thus supports the satisfaction of the dental technician, dentist and patient through higher safety, exceptional wearing comfort and fewer “recalls”.

THERMEO is smart.

Smart materials/responsive materials are materials that react independently to changing environmental conditions such as temperature. This reaction is reversible. The high-tech plastics of the THERMEO family belong to this group of smart materials and are characterized by a unique patented thermomemory effect. Compared to hard dental splints, inaccuracies during impression taking can thus be compensated with a THERMEO splint. THERMEO products can also be used to produce functional therapeutic bite splints. THERMEO splints are characterized by high wearing comfort and are self-adjusting due to the thermomemory effect. THERMEO’s special properties combine the advantages of hard as well as soft splint materials.

THERMEO is comfortable.

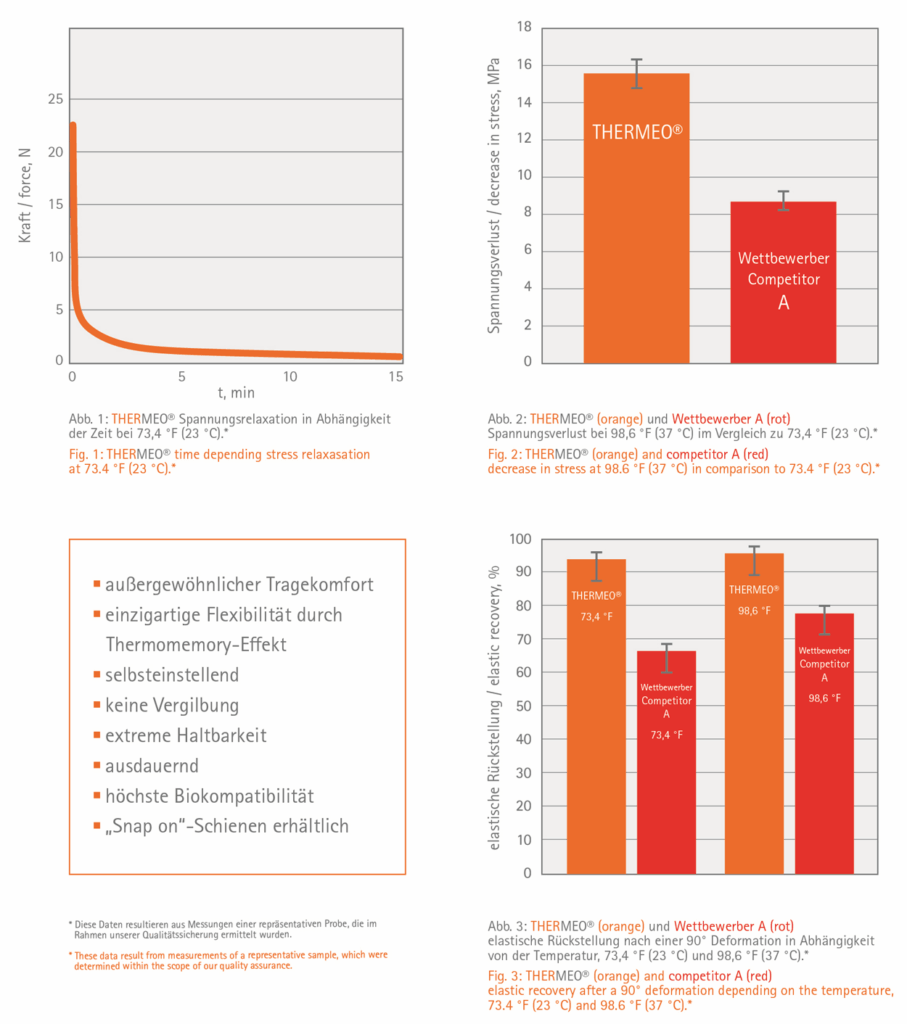

THERMEO meets the highest medical technology standards. For example, THERMEO does not use phthalate-based plasticizers, but instead employs a patented flexibilization technology that ensures unique biocompatibility in this class of material. Compared to other suppliers, this results in a significantly greater pressure drop on the tooth after insertion of the splint, which in turn increases wearing comfort for the patient. Furthermore, due to the technology used, the thermomemory effect and thus the resilience of the THERMEO material is greater than that of competitors. The THERMEO splint returns to its original position faster and more precisely due to body temperature. THERMEO can be processed conventionally using the casting or tamping-pressing technique or integrated into the digital workflow in the form of THERMEO blanks. The blanks are available in thicknesses of 16, 20 and 25 mm. This allows tooth-supported and also soft tissue-supported splints to be manufactured efficiently. The milling rounds are additionally available as THERMEO SO in shades A1, A2 and A3 for the fabrication of “snap-on splints”.

THERMEO is durable.

The materials of the THERMEO family, characterized by their exceptional wearing comfort, have been developed for durability. The stability of the material was documented in an extensive chewing simulation study conducted by LMU Munich**. Despite the higher flexibility and higher resilience of THERMEO compared to its market competitors, comparable abrasion values were determined. Thus, patient comfort is increased without reducing the clinical benefit. Furthermore, amine compounds and MMA were avoided in the development of THERMEO in order to reduce the yellowing of the material and its potential for irritation and sensitization. Furthermore, tested cleaning recommendations for THERMEO are available to the patient in order to sustainably ensure the special properties over the entire service life of the THERMEO splint.

** Prof. Dr. Dipl.-Ing. (FH) Bogna Stawarczyk, M.Sc · Felix Schmeiser, M.Eng

Werkstoffkundeforschung an der Poliklinik für Zahnärztliche Prothetik der LMU München

THERMEO splint Cleaning and Care

Comprehensive documentation and important tips on the use and care of THERMEO splints help you and the patients use THERMEO products for a long and sustainable time.

Processing

- Please store THERMEO liquid in a refrigerator at 41-48 °F.

- Prior to mixing both components must be refrigerated in order to ensure a long working time.

- Put the required amount of THERMEO powder into the refrigerator minimum 15 min. before usage.

- Mixing ratio 0,75 part liquid to 1 part powder (m %).

Important: respect mixing ratio thoroughly. - Mixing ratio can also be adjusted volumetrically.

- Mix it thoroughly for a approx. 5-10 sec. as quickly as possible and bubble-free (use separate mixing cup and spatula).

- Pour cold mixture immediately into the negative form.

If necessary please use appropriate separator. - Immerse in a pressure pot as soon as possible at > 2 bar and 122 °F for 45 min.

- After polymerization the splint can be finished as usual.

Safety notice

The company I.D.M di Marin Davide is not a manufacturer of medical materials or devices. The material sold on this site is neither produced nor controlled by the company I.D.M. di Marin Davide, who in no case can be held responsible for any damage caused by use or application of the material, which must only be used on suitable machines and by specialized personnel, exclusively for the purpose indicated, according to the manufacturer’s instructions. For resins with European certification, the properties of the finished product vary according to the entire printing and post-curing process; refer to the manufacturer for any information about it.

Reviews

There are no reviews yet.